Above: the result of five-hours work on a dead, dead, dead Univox 50-watt tube bass head. This model was originally designated the E-3 or the U-1236 (click here for the schematic). It was made in 1968, and it’s similar to a blackface Fender Bassman in many ways: fixed bias 50Watt output with a pair of 6L6s, 12Ax7 and 12AU7 preamp tubes, volume, bass, and treble controls, and a pair of switches marked ‘Sharp’ and ‘Deep.’ These switches are similar to the ‘Bright’ and ‘Deep’ switches that you would find on the two separate input channels of a Fender amp. Unlike the Bassman, the Univox uses an unusual additional balanced voltage amp between the phase inverter and the power stage. The Univox is also single-channel, it lacks middle and presence controls, and the power supply uses a voltage doubler.

Above: the result of five-hours work on a dead, dead, dead Univox 50-watt tube bass head. This model was originally designated the E-3 or the U-1236 (click here for the schematic). It was made in 1968, and it’s similar to a blackface Fender Bassman in many ways: fixed bias 50Watt output with a pair of 6L6s, 12Ax7 and 12AU7 preamp tubes, volume, bass, and treble controls, and a pair of switches marked ‘Sharp’ and ‘Deep.’ These switches are similar to the ‘Bright’ and ‘Deep’ switches that you would find on the two separate input channels of a Fender amp. Unlike the Bassman, the Univox uses an unusual additional balanced voltage amp between the phase inverter and the power stage. The Univox is also single-channel, it lacks middle and presence controls, and the power supply uses a voltage doubler.

Above, the Univox as I originally found it in a filthy old garage. It came with an empty pro-quality 2×15 ported instrument speaker cabinet; $45 was the total price. A bit steep, I admit, but I was feeling optimistic I suppose. I think a fair price for this thing would have been somewhere between ‘FREE’ and $25. Oh did I mention that it had no tubes in it either? I declined to take the speaker cabinet and it’s probably in a landfill now somewhere. Just can’t save ’em all…

Above, the Univox as I originally found it in a filthy old garage. It came with an empty pro-quality 2×15 ported instrument speaker cabinet; $45 was the total price. A bit steep, I admit, but I was feeling optimistic I suppose. I think a fair price for this thing would have been somewhere between ‘FREE’ and $25. Oh did I mention that it had no tubes in it either? I declined to take the speaker cabinet and it’s probably in a landfill now somewhere. Just can’t save ’em all…

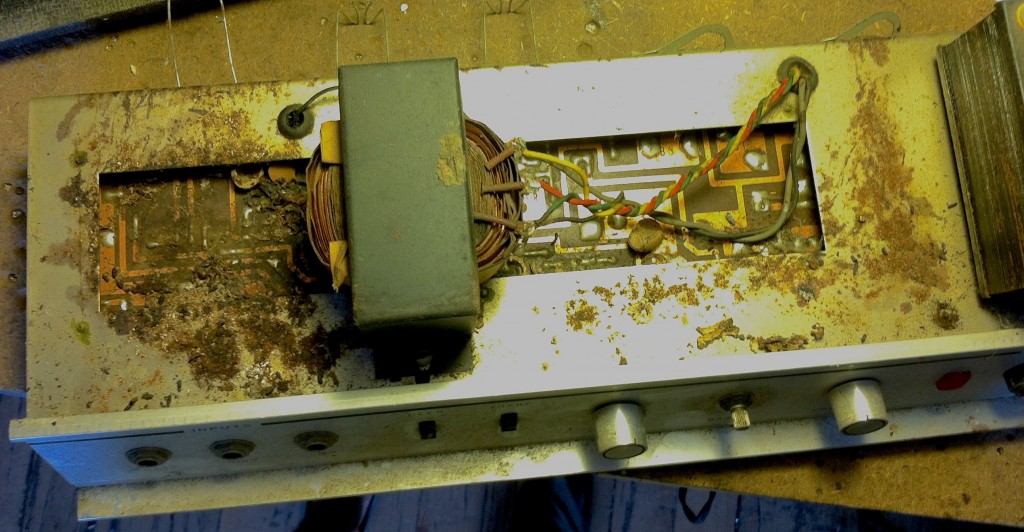

Hey there! Here’s the horrifying scene I encountered when I removed the single (incorrect) screw that was holding the chassis into the cabinet. What you are seeing is a heartwarming combination of acorn shells, spider eggs, and ants. Long after this thing ceased to be a device capable of amplifying audio, it had a second life as home for wayward animals. Let the crack fox explain. (click text at left for direct link; full video below).

Hey there! Here’s the horrifying scene I encountered when I removed the single (incorrect) screw that was holding the chassis into the cabinet. What you are seeing is a heartwarming combination of acorn shells, spider eggs, and ants. Long after this thing ceased to be a device capable of amplifying audio, it had a second life as home for wayward animals. Let the crack fox explain. (click text at left for direct link; full video below).

Oh yeah so – the horrifying part? Look at how this thing is constructed: a (basically non-removable) circuit board! With half of it obscured by sheet metal. This ain’t gonna be easy. Feeling a little less optimistic at this point…

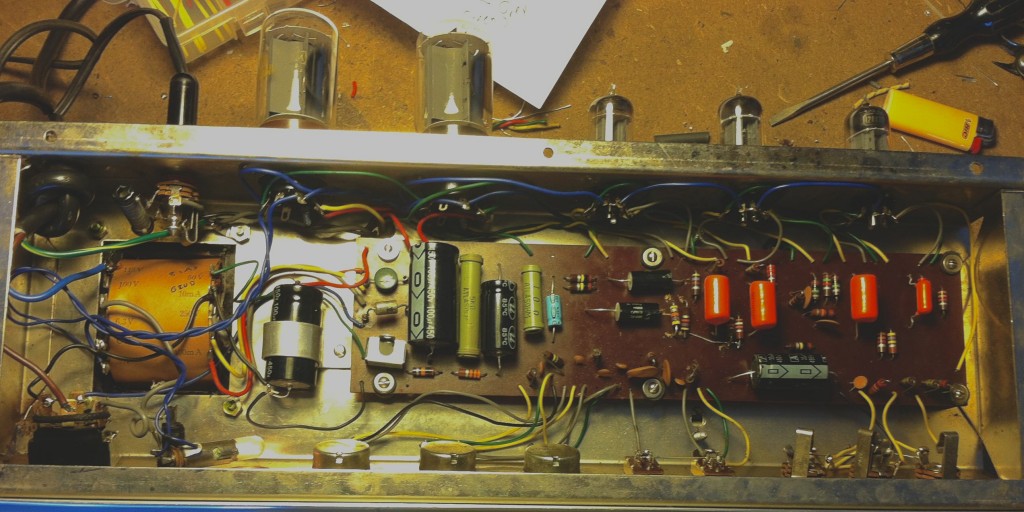

Above: the reverse side of the chassis (which was remarkably clean) after allllll of the repairs were completed. Here’s what it took:

Above: the reverse side of the chassis (which was remarkably clean) after allllll of the repairs were completed. Here’s what it took:

*When I found an appropriate-sized fuse cap and tubed the thing up, I attached the test speaker and I got… hummmmmmmm. That’s it. Lots of hum. Now as a younger fellow this would have discouraged me, but I’ve learned better. Hum may suck but it is SOUND, so at least the power transformer, rectifier, and output stage is relatively operational.

*I measured the voltages throughout the power supply – they were way off. One of the (factory-original) filter caps was so, so drastically underrated – 150v whereas it needed to handle at least 300v – so it’s a miracle this thing ever worked at all. Replaced all the filter caps (and the bias cap) and voila – some audio, a tiny, tiny bit, was passing from the input and the tone controls seemed to work. The B+ points were now also reading within appropriate ranges.

*After replacing the bias cap, the bias was reading 20v whereas the schematic indicated -32v. I was also getting two different readings at the 6L6 grids. I suspected the coupling caps, and sure enough, they were shot. replaced those and bias was now -28v and balanced. I little lower than the schem, but so was the B+ overall so probably correct.

*Next: started checking the B+ at every plate. ALL THREE 47K plate-load resistors were shot. As was EVERY SINGLE coupling cap in the amp. Replaced all of that stuff and the amp was working alright. Some hum, the tone sucked, but it was loud.

*As I was checking some voltages around the chassis I saw some sparking inside the output transformer. The O/T is a paper/wire wound unit with no potting or wrap whatsoever – the coils are completely exposed. Not a good idea. Anyhow, something, moisture, dirt, who knows, had gotten inside of it, and now that it was putting out some real current, it was starting to burn up. I had a spare output transformer (vintage US made unit from a discarded PA head) with the same turns ratio, same size and weight, so I threw that in. Now the amp sounded great! Almost done…

*Last steps: removed the two-prong A/C cord and the ‘Death Cap,’ replaced the DPDT power/standby switch (the original switch was intermittent), and put in a better-matched pair of output tubes (a pair of old Sylvania 5881s). I used 50s RCAs for the preamp. Hum is totally gone, everything works great. It’s really a great-sounding amp now – loud, versatile controls, and so small and light for a 50W head. Pretty good, pretty neat…

As far as the cosmetics go: one of the original knobs was missing and I didn’t have an identical unit in stock, so I replaced all three with some vaguely period-correct Japanese knobs. I also didn’t have a Univox logo plate to replace the missing original, so I added a name plate from the random-logo-drawer onto the front of the amp just because it looked a little odd with nothing there. Univox is now ready to go, much better than it was from the factory: better caps, better output trans, and much better tubes too. If this had been a repair for a customer, the bill would have been around $400 for parts and labor (assuming I used new Chinese or Russian tubes and a new O/T). $400 is clearly too much for a sensible person to spend on repairing a piece like this, as the street value for a properly working unit is only about $350. Had someone other than an amplifier serviceman purchased this thing, it probably would have gone into the trash or into another garage for the next 45 years. Now, if the Univox had been wired and assembled like a Fender amp, on a turret board, the repair would have taken half as much time and the repair could have been vaguely cost-effective. It was the goddamn awkward circuit board that made it take so long to re-fit. Proof yet-again that repairman-friendly construction practices do add significantly to the service-life of an amplifier.

As far as the cosmetics go: one of the original knobs was missing and I didn’t have an identical unit in stock, so I replaced all three with some vaguely period-correct Japanese knobs. I also didn’t have a Univox logo plate to replace the missing original, so I added a name plate from the random-logo-drawer onto the front of the amp just because it looked a little odd with nothing there. Univox is now ready to go, much better than it was from the factory: better caps, better output trans, and much better tubes too. If this had been a repair for a customer, the bill would have been around $400 for parts and labor (assuming I used new Chinese or Russian tubes and a new O/T). $400 is clearly too much for a sensible person to spend on repairing a piece like this, as the street value for a properly working unit is only about $350. Had someone other than an amplifier serviceman purchased this thing, it probably would have gone into the trash or into another garage for the next 45 years. Now, if the Univox had been wired and assembled like a Fender amp, on a turret board, the repair would have taken half as much time and the repair could have been vaguely cost-effective. It was the goddamn awkward circuit board that made it take so long to re-fit. Proof yet-again that repairman-friendly construction practices do add significantly to the service-life of an amplifier.